With over 15 years of experience, Valland Spa is a distinguished OEM in manufacturing On/Off valves for the Oil, Gas, and Energy Industries.

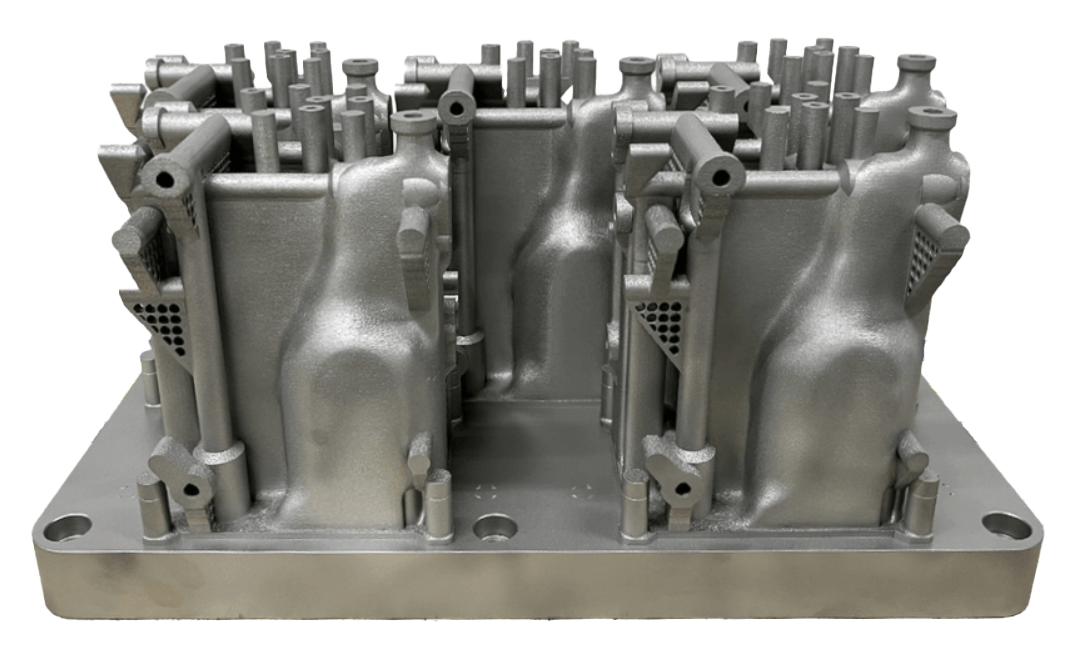

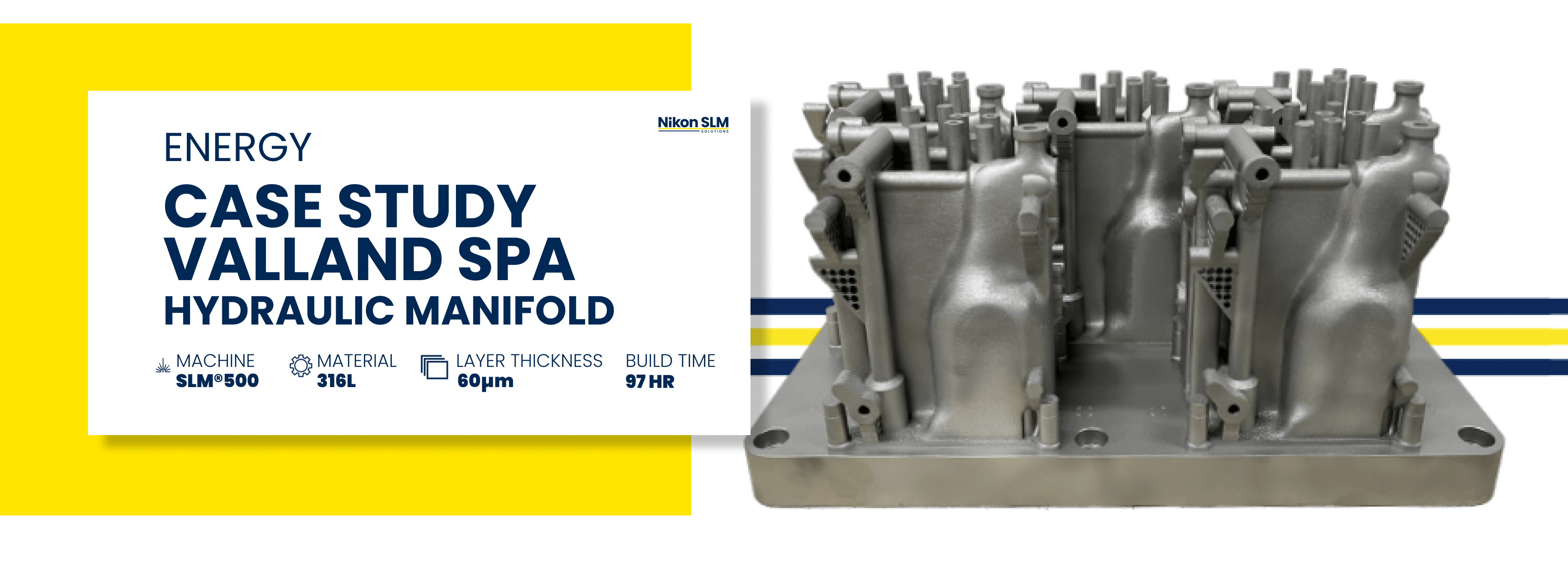

Faced with the challenges of traditional manufacturing methods, Valland Spa embarked on redesigning the manifold component. The objectives were clear: maximize stiffness, reduce weight, optimize topology, cut down on production lead time, and ensure component customization.

Traditional vs. Additive Manufacturing Lead Times. Discover how additive manufacturing reduced lead times from 2-3 months to just 3 weeks. Explore the full case study for insights and learn how Valland Spa transformed valve manufacturing using Nikon SLM® technology.

Want to take off with your own application? Download this case study for a comprehensive insight.

For further information, talk to our experts!

DOWNLOAD NOW

Don't miss out on the opportunity to stay ahead of the competition and unlock the full potential of your manufacturing process. Download your copy below!