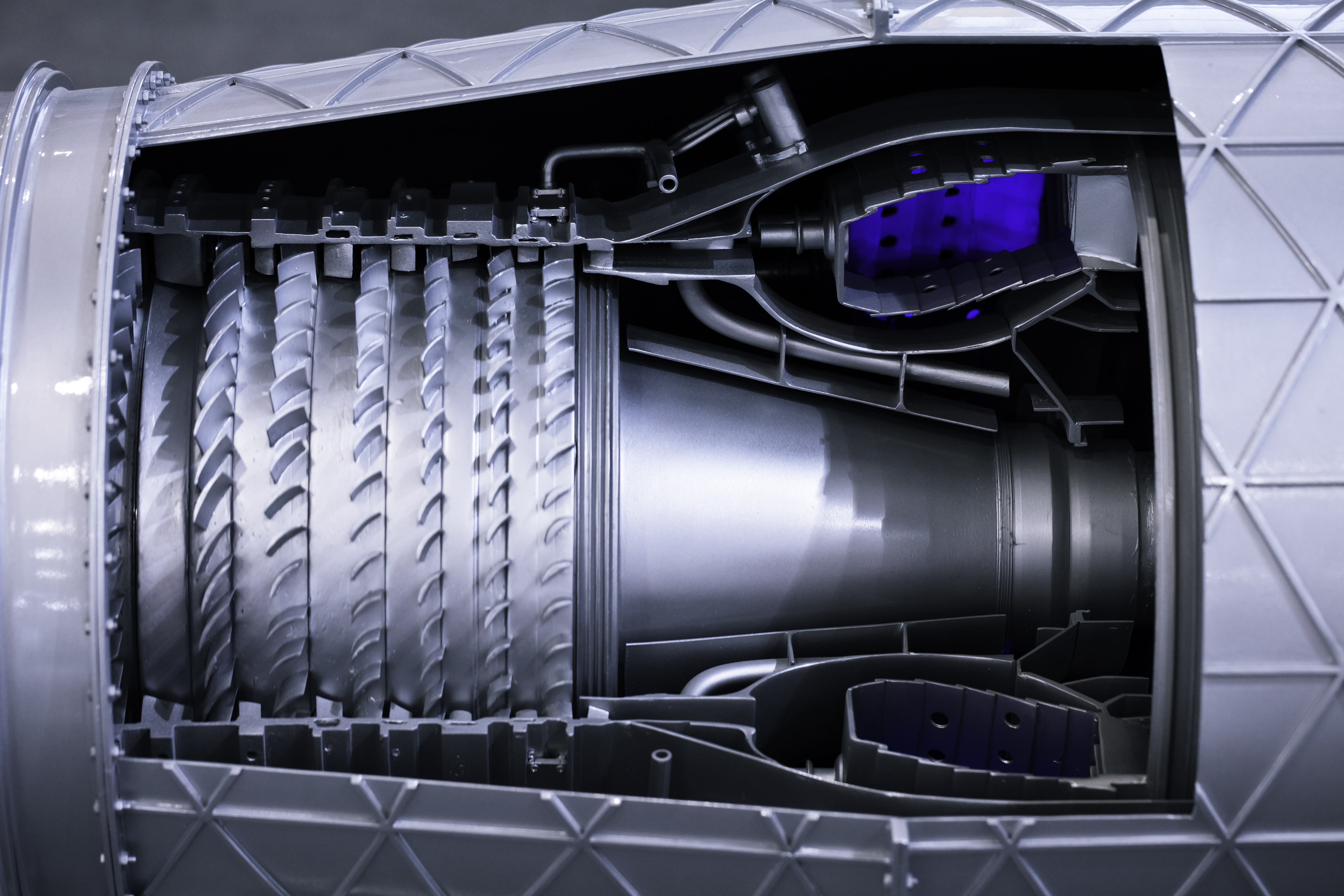

Additive Manufacturing for the Energy Industry

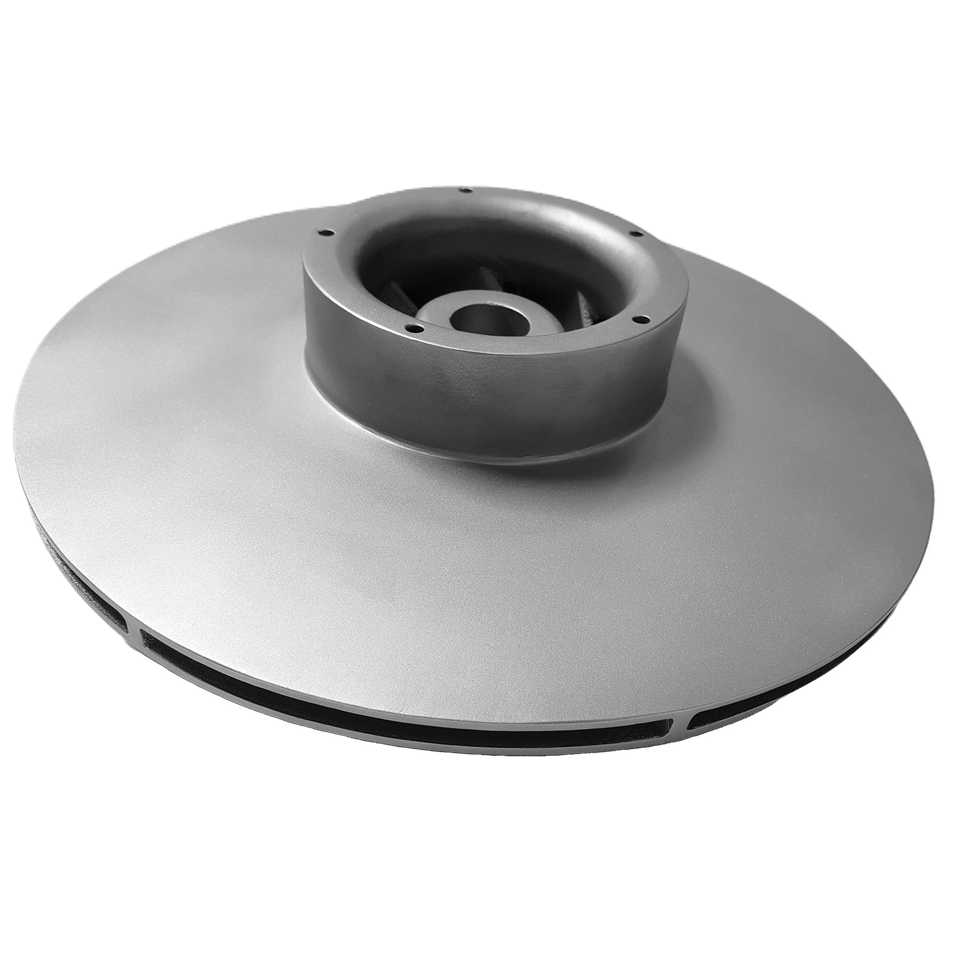

Metal 3D Printing Solutions for Energy

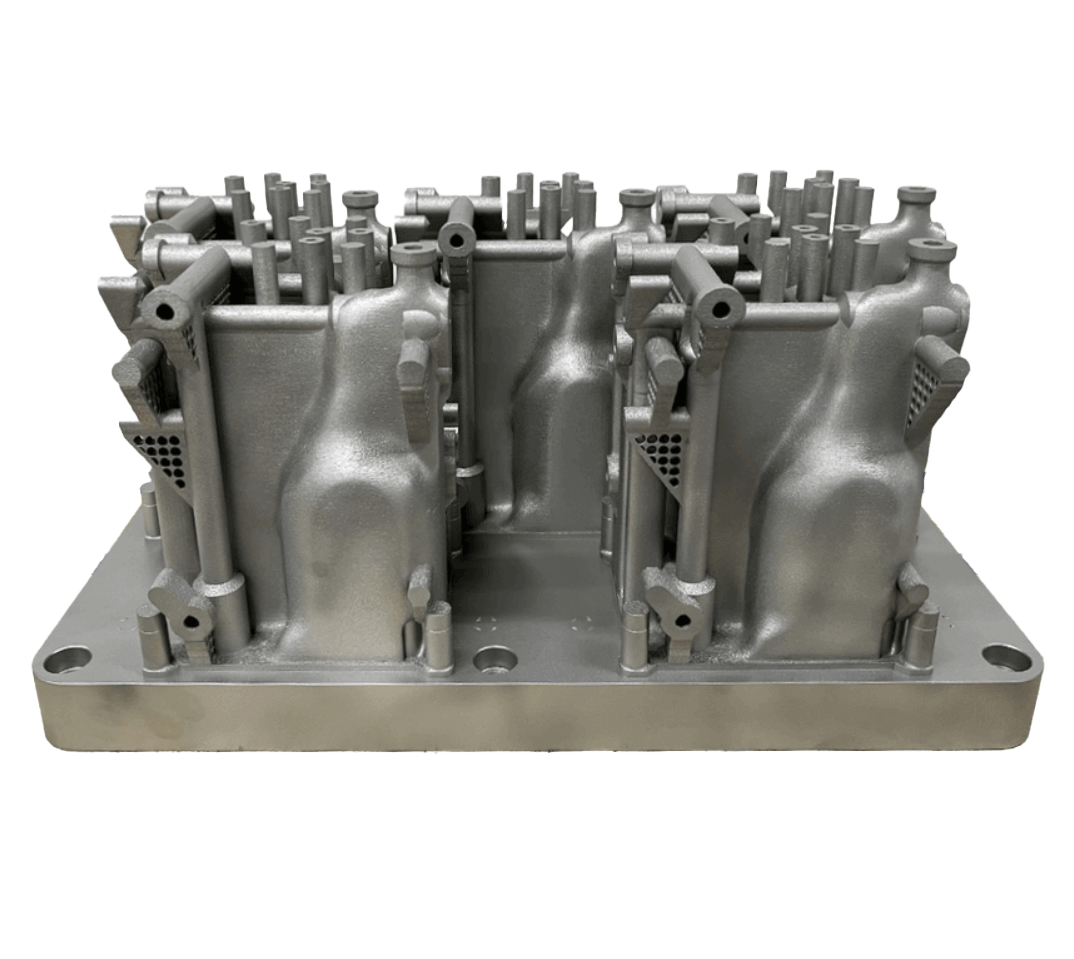

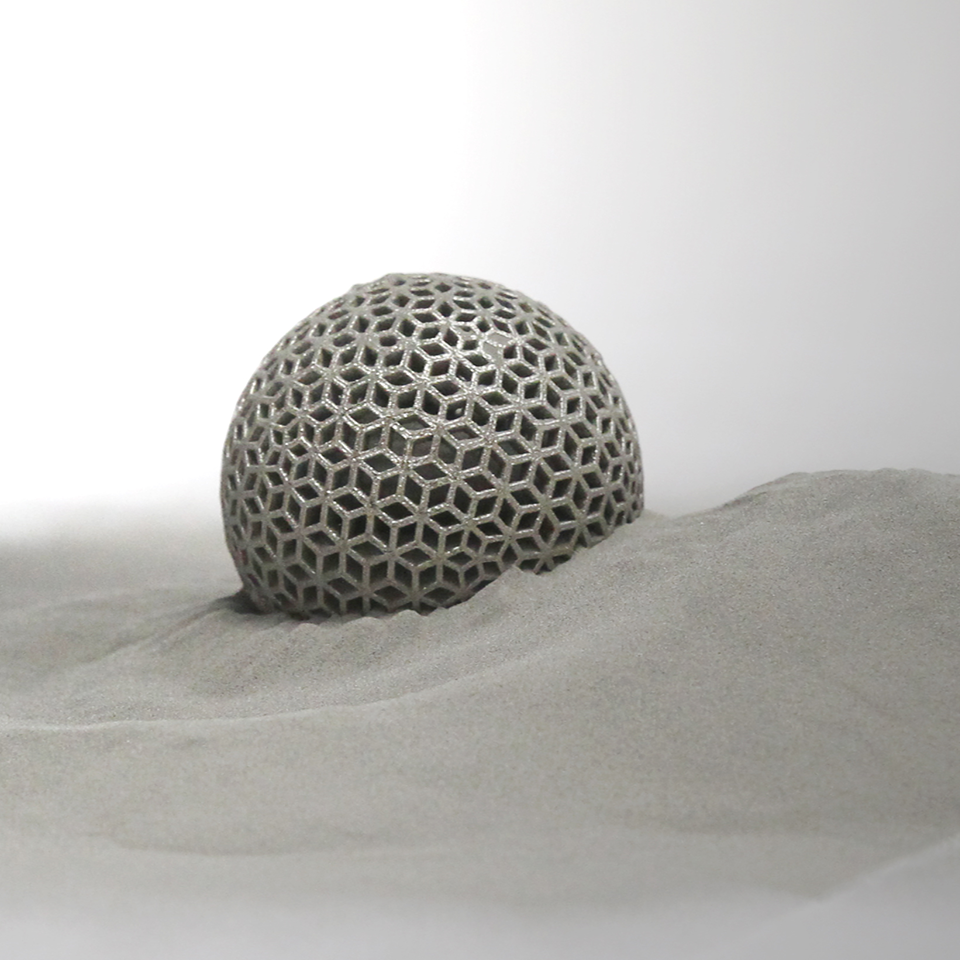

Power up your additive manufacturing for the Energy sector. The Energy industry is known for low-volume, high-mix, making it a viable production line for a highly agile industry. Yearly production volumes range from hundreds to thousands of parts per year, per part design. The elimination of tooling, full design flexibility and being able to immediately redefine production planning are key enablers of a smart and lean supply chain.

The traditional business model of energy operators incur a surplus of immobilized capital of spare parts because of procurement lead time and asset downtime cost. AM is measuring parts production and delivery into days opposed to weeks or months enabling the most efficient just-in-time production scenario.

Whether you are making one or many, test the waters with AM – we help ensure your success with metal additive manufacturing. Find out more about the numerous manufacturing possibilities using SLM® technology in the Energy industry below.

SLM® Material for Energy Applications

Nikon SLM Solutions sells appropriate powder and parameter sets for the most common powders in the energy industry:

- Ni-Based Alloys: IN625, HX, IN718, IN939

- Fe-Based Alloys: 316L (1.4404)

- Cu-Based Alloys: CuSn10

Selective Laser Melting Solutions for Energy Applications

Quality Standards for Energy Industry

We are experts when it comes to qualifying metal parts on our machines, and we are ready to help you each stage of the process. Nikon SLM Solutions supports energy projects with relevant documentation, certificates, pFMEAs, parameters, powders, and more. Allow us to share our knowledge with you to boost your metal additive manufacturing production, contact us today!