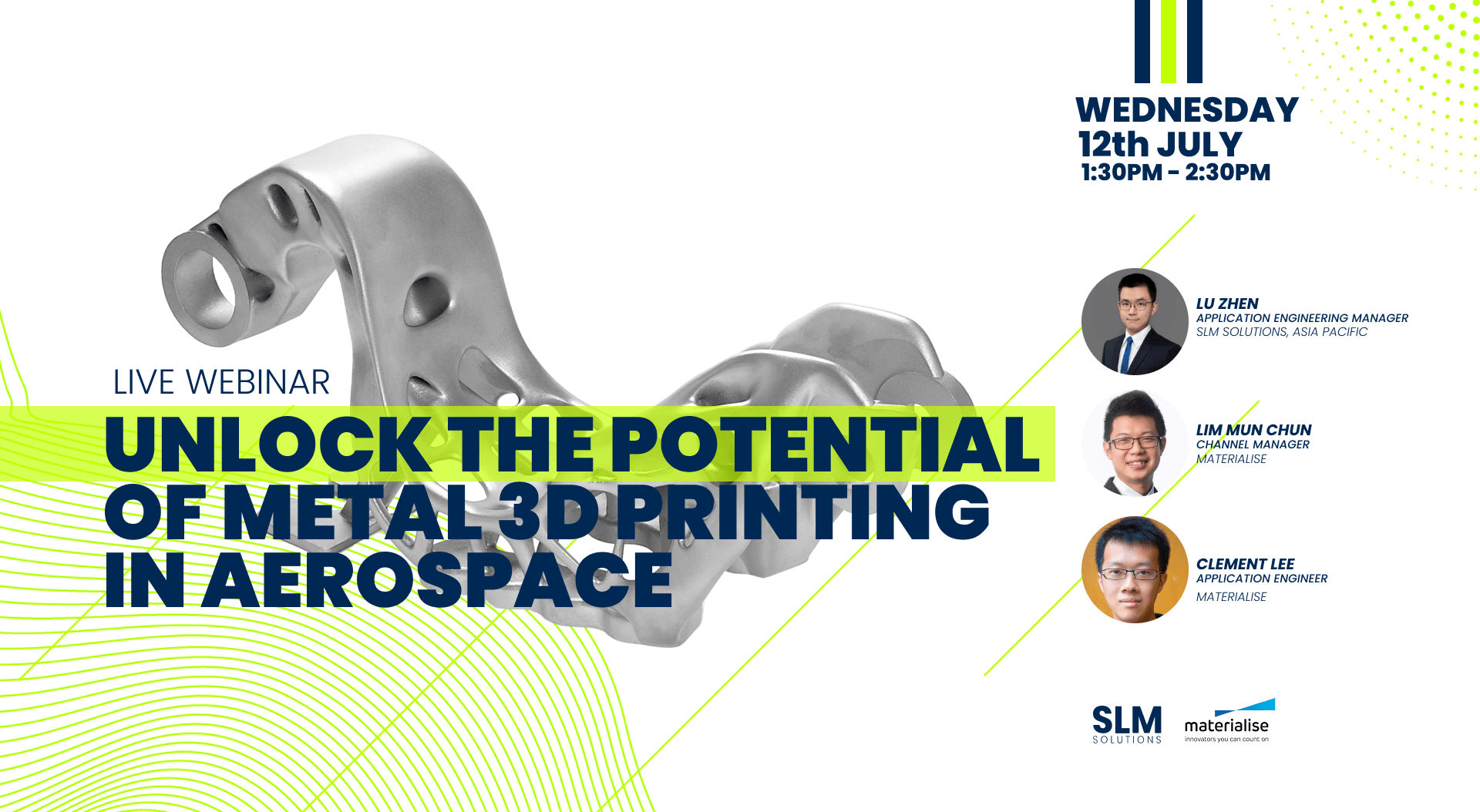

UNLOCK THE POTENTIAL

OF METAL 3D PRINTING IN AEROSPACE

Metal 3D printing, also known as Metal additive manufacturing, has been a game-changer for the aerospace industry. It combines the design capabilities of additive manufacturing with the mechanical properties of metal. In order to utilize this technology as efficiently as possible, many wonder how they can combat the three main cost drivers of metal AM: time, material consumption, and machine use.

Join Materialise and SLM’s experts in a conversation where we share how our software and hardware solution can help you to optimise the support generation and quality control process, making the most out of metal 3D printing.

Key Learning Point:

- Automated quality control using data gathered during the 3D printing process

- Leverage AI capability on powder bed layer images to consistently identify scrap & risk, reduce post-processing cost and gain better insights.

- Learn how SLM Solutions’ Free Float technology enables customers to benefit from the robustness of a material without incurring additional post processing costs.

- Aerospace case study

Speakers:

Lu Zhen has been in the industry of Additive Manufacturing (AM) for 10 years with proficiency in various industrial AM systems and software. He has rich theoretical and hands-on experience in the topics of AM, material science, process parameters of laser systems and Design for AM (DfAM) etc. In his current role, he focusses on providing technical solutions to customers and helping them maximise their investment in Metal 3D Printing. Prior to joining SLM Solutions Singapore, he was with Singapore Centre for 3D Printing (SC3DP) and NTU Additive Manufacturing Centre (NAMC). Lu Zhen received his Bachelor of Mechanical Engineering from Nanyang Technological University (NTU) and is currently pursuing his part-time PhD at Singapore Centre for 3D Printing (SC3DP), Nanyang Technological University (NTU) in the topic of Selective Laser Melting.

Lim Mun Chun is the Channel Manager for Materialise and leads the channel activities in South East Asia, Australia & New Zealand and India region with focuses on overall strategy for business development and foster client relationships. For the past 7 years in the AM industry, he has developed vast experience on overall AM industry in Asia Pacific. He is now leveraging knowledge and experience gained on the market and help organizations to optimize their AM through software solutions and consultancy in Materialise.

Clement Lee is an Application Engineer at Materialise responsible for Additive Manufacturing software. Aside from being the first point of contact for technical inquiry regarding Materialise software, he gets to work with a number of end-users spanning multiple countries for different AM applications. His current focus is on data preparation for additive manufacturing in various main technologies.