Learn how Uniformity Labs utilized the industry-leading SLM®125 to achieve a 1.5X reduction in build times for metal parts while maintaining quality and performance.

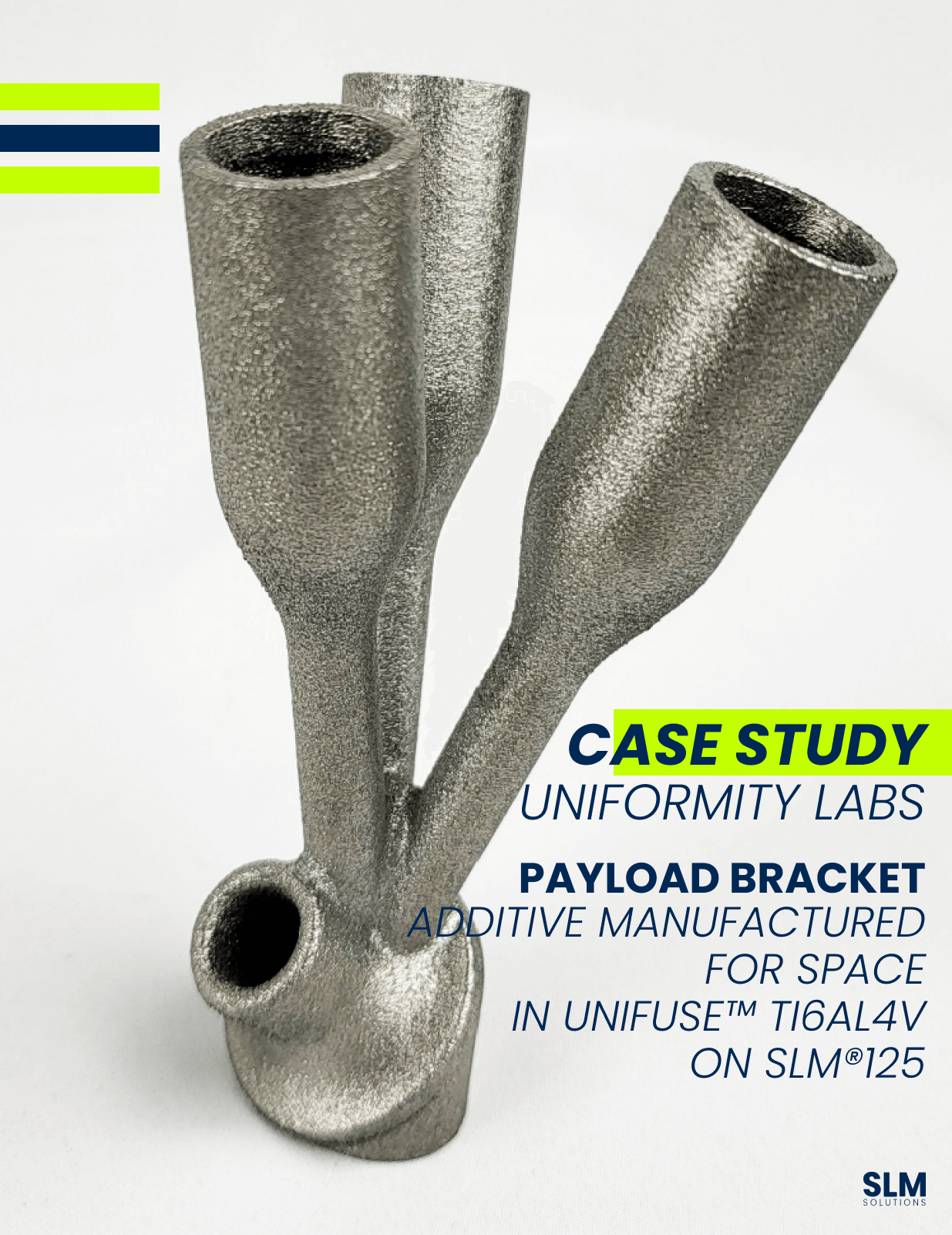

By utilizing SLM® technology with UniFuse™ Ti6Al4V powder and high-performance scanning parameters, the company produced a high-quality payload bracket for an aerospace company with superior mechanical properties, reduced weight, and reduced costs compared to traditional manufacturing methods.

Want to take off with your own application? Download this case study for a comprehensive insight.

For further information, talk to our experts!

DOWNLOAD NOW

Don't miss out on the opportunity to stay ahead of the competition and unlock the full potential of your manufacturing process. Download your copy below!